Thermal Transfer Ribbons

Why TSC Thermal Transfer Ribbons?

Maximise the life of your printheads and enjoy consistent print quality!

Benefit from different sizes available directly from stock!

Order any time: our Ribbons are ready for immediate dispatch with minimum order quantity of just one box!

Choose from the most complete range of Thermal Transfer Ribbons' formulations with wax, wax-resin and resin!

Go sustainable with a green choice of all halogen-free TSC Ribbons!

Go safe in food packaging! TSC ribbons are approved for food contact marking/coding and comply with GHS regulations.

Genuine Supplies Free Samples

Not sure which Thermal Transfer Ribbon meets your requirements? Simply fill out the form below and get started today!

More than just a Ribbon

When you choose TSC Genuine Supplies, you’re not just purchasing high-quality ribbons — you’re also supporting a greener planet. For every purchased ribbon box, we plant a tree.

Trees are the foundation of a thriving, healthy planet. They regulate climate, improve air quality, promote soil health and support biodiversity by providing natural habitats for a wildlife. These green giants play a crucial role in water management, efficient energy consumption, provide economic benefits through ecotourism and contribute to mental and physical health.

In our mission for sustainable future, we partner with Treecelet who’s mission is to significantly enhance the planet‘s green cover and support thriving ecosystems. Through this partnership with Treecelet, we plant mangrove trees in coastal Kenya restoring biodiversity, generating income streams, stabilising coastlines and local communities threatened by poverty.

Each purchase contributes to the creation of lush forests, thriving wildlife, and happier communities.

TSC Formulations

Wax

Our exclusive line of wax ribbons offers excellent print quality for a variety of applications. Wax is ideal for general-purpose use and offers the best possible value.

Available in two high-end formulations:

8050 - SWX – TSC STANDARD WAX

- Widely used for barcode applications

- Provides excellent print quality

- Suitable for standard labeling applications

- Compatible with most coated and non-coated paper labels

8300 - PWX – TSC PREMIUM WAX

- Resin-enhanced wax

- Best scratch and smudge resistance for a wax ribbon

- Supports high-speed printing Excellent print quality on all papers and some film materials

Wax/Resin

Wax-resin is a versatile, multi-purpose ribbon for challenging environments. The combination of wax and resin provides the printer with the ability to print on various materials such as synthetics, coated or glossy paper stocks, while also offering protection against chemicals, smudges and smearing.

Available in two high-end formulations:

8500 - SWR – TSC STANDARD WAX/RESIN

- General-purpose wax/resin formulation.

- Superior print quality on common papers and films.

- Our most versatile formulation with good scratch and smudge resistance.

8550 - PWR – TSC PREMIUM WAX/RESIN

- Designed to print on a wide range of coated papers and films.

- Very sharp print quality, enabling ladder and rotated barcode printing simultaneously

- Enhanced abrasion and scratch resistance

Resin

This is the best ribbon for extreme environments where high-quality images and resistance against scratch, smudge, heat, liquid, or chemicals are required. Resin ribbons are usually used with synthetic labels; they do not print well on paper labels.

8650 - SRE – TSC STANDARD RESIN

- Excellent mechanical resistance, including abrasion and scratches.

- Extensive adaptability to a wide range of film materials.

- Supports higher print speeds.

8770 - TSC PRE PREMIUM RESIN

- Developed for extreme environmental labeling.

- Unmatched scratch and solvent resistance.

- Maximum durability.

Winding Direction

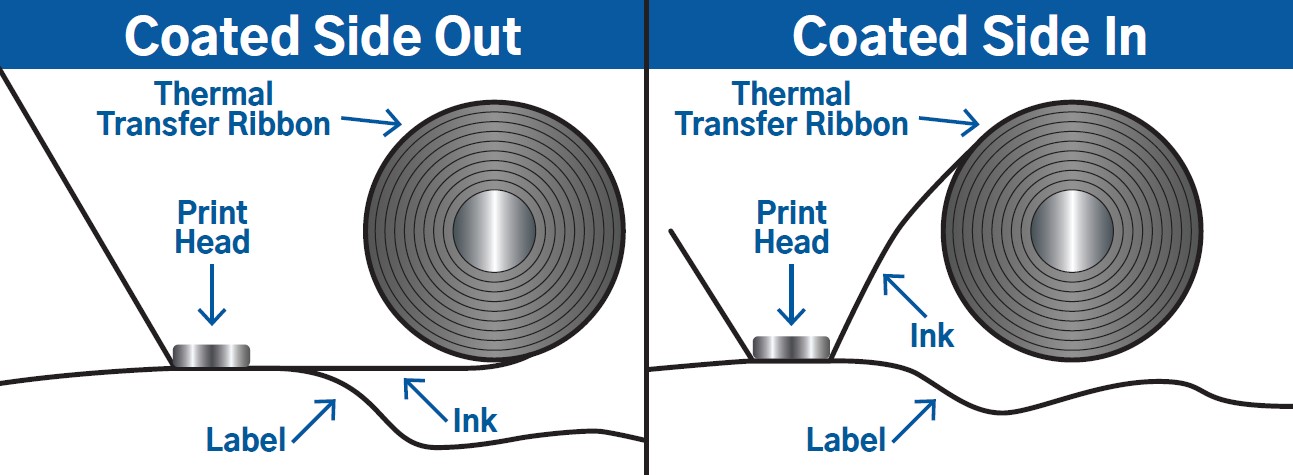

There are two categories: coated side out (OUT) and coated side in (IN). This designation pertains to the placement of the ink coating on the ribbons. It influences the winding and feeding process through the printer, as most printers are designed to accommodate only one of these styles.

Coated Side Out Ribbons

Coated side out ribbons are printing ribbons with the ink coating facing outward. You'll observe that the ink is on the exterior of the ribbon roll, unrolling from the bottom before coming into contact with the print head and label.

Coated Side In Ribbons

Coated side in ribbons are printing ribbons with the ink facing inward. You'll observe that the ink is on the inside of the ribbon roll, unrolling from the top before coming into contact with the print-head and label.

Ribbon Size

When selecting a thermal transfer ribbon size, there are a couple of additional criteria to consider:

- Label width

It is recommended to choose a ribbon width slightly wider than the label width, typically by approximately 3-5mm. This ensures that the ribbon provides protection to the printhead, preventing rubbing of the label that may otherwise damage the printhead. - Ribbon length

Ribbons with shorter lengths are typically designed for desktop thermal transfer printers, whereas longer lengths are intended for industrial printers. Our stock range includes ribbons ranging from 90 to 625 meters. - Core size

Smaller printers may have limited space to accommodate larger ribbon cores. While a 1-inch core is standard, smaller printers often use a 0.5-inch core.

Frequently Asked Questions

What should I consider before choosing a Thermal Transfer Ribbon?

When choosing which Thermal Transfer Ribbon to go with, first consider the following:

- What do I need the Thermal Transfer Ribbon for?

- Do I have specific requirements such as isopropyl alcohol or ethanol or UV durability?

- What is the substrate I need to print on e.g. PP, PE, PET?

- Do I have a near-edge or a flat-head printer at my disposal?

- What settings does my printer type allow me for?

This way, by harmonising ribbon, substrate, printer type and printer settings and application, we can assure of producing the ultimate print result.

How can I try Thermal Transfer Ribbons?

You can always request a sample free of charge to try our TTR in your own production environment. Additionally, we also offer testing support in our in-house lab or on-site, so feel free to get in touch with us to discuss your future projects and opportunities.

Does TSC offer a warranty over its ribbons?

TSC Auto ID gives a warranty for a period of 12 months after date of delivery to customer.

Can I choose the specifications of the Thermal Transfer Ribbon to my liking?

TSC offers great flexibility when it comes to ribbon grades, sizes, colours or cores. We can manufacture ribbons which will surely meet your expectations. Contact us

How can I place an order?

You can send your request here and one of our sales representatives will get in touch with you regarding your order.

How should I store my ribbons?

The storage guidelines for thermal transfer products are as follows:

- Store at room temperature, 5-35°C, 20-80% relative humidity

- Keep away from heat and direct sunlight

For qualities that light up under UV-light, Resin UV Black and Resin UV transparent, an additional guideline applies:

- Keep the box closed to avoid daylight as much as possible, as this affects the product’s luminescence

Genuine Supplies Catalogue

Our Genuine Supplies Catalogues are exclusively available for our Partner Portal Account holders. Please note you will only be able to download these catalogues if you are logged in to your account.

To log into your account, please click here.

To request a Partner Portal account, please click here.

Download Euro Catalogue Download USD Catalogue Download GBP Catalogue