Flexographic Labels

Meet Colour Labels

Modern print needs to strike a perfect balance between craft and technology. We never forget about the environment, always offering the best solutions for the most discerning public.

TSC Genuine Supplies (powered by MGN) has manufactured printer consumables (labels, TTR tapes), implemented label marking and printing equipment, mobile terminals and RFID technology, and designed and constructed comprehensive printing and labelling systems for more than a decade. It leads the pack among companies that take a holistic approach to product labelling, quickly responding to the changing market. Our experience allows us to always stay a step ahead of the competition, while being able to help our business partners save time and resources.

What is Flexographic Printing?

Flexographic printing is a modern rotary printing process that uses flexible photopolymer plates, wrapped around printing cylinders, to transfer ink directly onto a substrate. Each colour requires its own plate, produced in a separate process, and as the material moves through the press it passes under multiple plates mounted on cylinders. Ink is delivered from special ink wells to the plates and then onto the substrate, making the process fast, efficient, and well-suited for high-speed label printing.

Originally developed in the 19th century and once associated with low-quality results, flexography has advanced dramatically in recent decades. It now enables precise, economical printing on a wide variety of challenging materials, including foil and non-porous substrates, using fast-drying inks. With up to 10 printing stations, the technique supports highly complex graphic designs and a range of finishing options such as glue printing, substrate printing, peel-off printing, cold stamping, varnishing, and lamination—opening up a whole new world of possibilities for modern print production.

Advantages of Flexographic Label Printing

Flexo printing is highly versatile. It is most often touted for its combination of speed, quality and economical print options. But it also has many other advantages including:

Varied Sizing Options

Our flexographic label presses can print up to 20" wide – allowing for large format labels. Additionally, we can save time by simultaneously printing several streams of labels side-by-side.

Substrate Choices

Because a flexographic label press applies ink directly on the substrate, it allows for an extremely wide variety of substrate options. Everything from metallic films and foil to acetate and paper can be printed with a flexographic press.

Versatile Inks

Flexo presses can use a variety of inks including water-based, fluorescent, metallic, and UV-curable inks.

Inline Finishing

Finishing options including topcoats & laminating, turret rewinders, sheeters, and fanfolders can be added to finishing stations at the end of flexographic presses. This allows for continuous production and time savings.

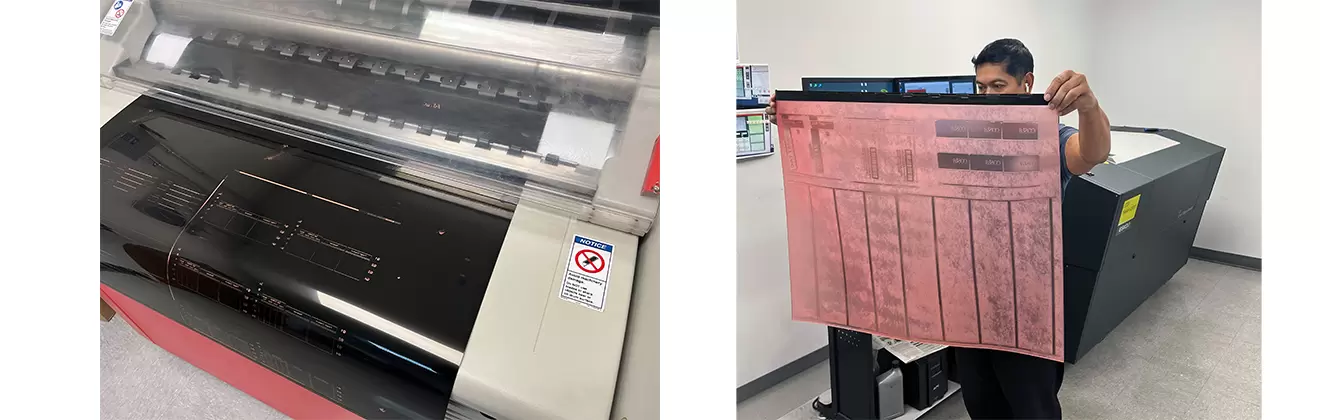

Our In-House Prepress and Plate-Making

We handle every stage of prepress and plate making in-house, ensuring complete control over cost, quality, and turnaround time.

Our centralised art and DTP (desktop publishing) teams prepare all artwork and rasters on-site, carefully verifying every file before it enters production. Flexography is one of the most demanding techniques when it comes to prepress, which is why our skilled professionals oversee each stage of the process - aligning design with material, technology, and graphics to achieve the best possible label appearance.

We also operate our own CTP (computer-to-plate) room, using cutting-edge imaging technology to create durable, high-quality polymer plates. These plates can be reused multiple times, making the process both economical and sustainable. By managing everything internally - without subcontractors or long material delivery deadlines - we guarantee consistent quality, faster lead times, and cost-effective solutions for our customers.

Graphic Design Studio

Consumers do not buy a product, but the story that it tells. This is why our printing house also offers graphic design services.

Thanks to our specialists, including experts in brand image communication, we can create a perfect design to reflect everything you would like to see in your product. Our graphic designers all have the soul of an artist and the brain of a marketing analyst.

Labelling should look good but it also needs to achieve a goal: to sell a product. As we design your label, we ask ourselves: why?

Making sure our design is communicative, we reach out to the right customers and improve your sales statistics.

How? Tell us your idea and we will take care of the rest.

What we can do:

Printing & Materials

• Flexographic printing up to 11 colours

• Wide range of synthetic and non-synthetic materials

• Adhesive-side printing

• Back printing

Finishing & Enhancement

• Lamination and varnish

• Cold stamping with specialty films (metallic, holographic, and more)

• Custom die-cutting and slitting

• Custom finishing

Specialty Label Formats

• Fanfold labels

• Expanded content labels (multi-layer and booklet)

• Graphic design and prepress