Driving Fulfilment Excellence to Elevate Retailer Experiences for Weyco Group

Background

Weyco Group, a leader in the footwear industry with over 50 years of experience, operates across the United States, Canada, Australia, and beyond. In the U.S., their footwear is sold through major retailers like JCPenney, Macy’s, Nordstrom, and Kohl’s.

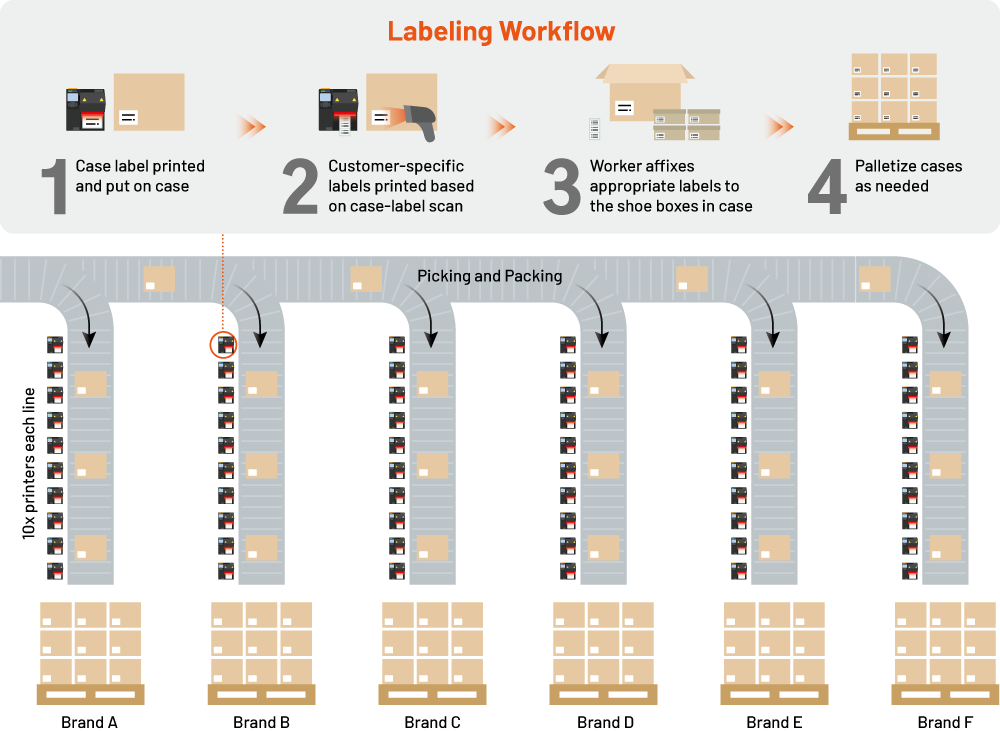

At their Milwaukee, Wisconsin main warehouse, Weyco runs six fulfilment lines, offering value-added services such as custom and RFID labelling for their retail partners. Each fulfilment line is equipped with ten printers dedicated to printing different label configurations, ensuring they can accommodate a specific retailer’s labelling needs without the need to stop their lines to reconfigure. This allows products to move efficiently from the warehouse to outbound trailer loading without interruption.

Challenges

Many of Weyco’s retail customers make frequent orders of a few shoe pairs at a time destined for specific stores. Picking, sorting, and case-lot packaging large numbers of these small orders presented unique challenges Weyco had trouble solving with their previous fleet of up to four printer brands. The top issues Weyco had to address included:

Managing High-Volume, Continuous Operations

Handling over five million labels annually, Weyco’s printers needed to be highly reliable. Any downtime required another line to step in immediately. Discrepancies in label settings across different printer brands made this challenging.

Improving Barcode Verification

Weyco’s initial printers lacked accuracy when verifying barcodes during printing. This led to manual reprinting, reducing overall efficiency.

Adapting to RFID Labelling Requirements

As RFID labelling became essential to Weyco’s customers for better in-store inventory management, they asked Weyco to add this service in their fulfilment centres. Weyco required a solution that wouldn’t necessitate replacing their entire system. Many printers struggle to handle different RFID label types or easily switch between them during operations.

Centralised Management of a Large Printer Fleet

With 60 printers spread across the warehouse, Weyco needed centralised control. Managing firmware updates across all their warehouses and printer brands often took more than a month, underscoring the need for an efficient, unified system.

Solutions

Over the past fifteen years, TSC Auto ID has become the dominant printer brand in the Weyco Group Milwaukee warehouse by consistently helping them address the above challenges. Here’s how.

High-Performance Printers for Continuous Operations

TSC Auto ID’s enterprise-grade printers, including the T6000e and T8000, handle over 10,000 labels daily. These printers support multiple saved label settings, allowing for quick transitions between lines on Weyco’s Value Add Services (VAS) line, where they apply additional labels such as product IDs and RFID inventory tags. With support for nine major printer language emulations, TSC Auto ID printers ensure label compatibility without having to reprogram their systems, reducing downtime and enhancing productivity.

Jason Russ, Director of Information Systems at Weyco, highlighted TSC Auto ID’s support: “Your technical support has been invaluable. When we faced unsolvable problems, your team showed up, troubleshot, and resolved the issues, even handling firmware updates for us.”

Automated Barcode Verification

TSC Auto ID’s ODV-2D Barcode Verification solution grades every barcode against ISO quality standards. If a barcode fails, the system automatically strikes through and reprints the label, eliminating manual intervention and maintaining operational speed.

Russ further emphasized the importance of the solution: “The outstanding ODV ensures we put good labels on the shoe boxes and don’t send bad ones out the door.”

Enhanced RFID Label Printing

TSC Auto ID’s RFID-equipped printers enable Weyco to provide their customers with RFID labels on each shoe box. This enhances accuracy and helps find “lost” shoe boxes to save sales that might otherwise walk out the door. Weyco and TSC Auto ID directly help these customers drive better retail performance.

Like with ODV, TSC Auto ID’s RFID solution ensures every tag is readable. If a newly programmed tag is unreadable, the printer destroys it and strikes through the label so it’s not mistakenly applied to a box, and then encodes, verifies and prints the next label so workers never miss a beat and retailers never receive a box with a faulty tag.

Modular Printer Design for Scalability

TSC Auto ID’s modular printer design enables Weyco to easily upgrade existing printers with additional features, including RFID and ODV-2D, without the need to replace the entire printer. This flexibility allows Weyco to adapt quickly to evolving customer needs, seamlessly switching between different label constructions. The modularity not only future-proofs their investment but also reduces downtime and operational disruptions by allowing upgrades and maintenance to be completed efficiently.

Centralized Printer Management with PrintNet Enterprise

TSC Auto ID’s PrintNet Enterprise (PNE) software empowers Weyco to remotely manage their entire global fleet of printers from a single platform. Whether updating firmware, diagnosing issues, or configuring settings across multiple locations, PNE has streamlined Weyco’s global operations, improving efficiency and reducing downtime. This centralised management capability ensures that Weyco can maintain consistent performance and operational control, no matter where their printers are located.

Why TSC Auto ID?

Weyco Group partners with TSC Auto ID for their Milwaukee, Canada, and Australia locations, trusting the printers for their unmatched reliability, efficiency, and excellent return on investment (ROI).

Durable and Dependable

During a recent troubleshooting, Gonzalo Nieto, IT Technical Specialist, found a printhead that had been working for fifteen years. This exceptional durability is vital for supporting Weyco's continuous, high-demand operations.

Advanced Features

TSC Auto ID’s ODV-2D and RFID-equipped printers provide cutting-edge solutions for barcode verification and RFID encoding. The ODV-2D system automates barcode verification to ensure only high-quality, compliant barcodes are produced, reducing errors and shipment rejections. RFID-equipped printers efficiently encode RFID tags for improved customer inventory tracking and supply chain visibility.

Exceptional ROI

TSC Auto ID printers deliver significant cost savings and operational efficiency for Weyco. By extending the life of their existing printers with modular upgrades like the ODV-2D and RFID kits, Weyco has avoided the higher costs of replacing equipment entirely. These modular enhancements allow Weyco to meet evolving business needs without requiring new hardware investments, maximising their return on investment while maintaining operational flexibility. PrintNet Enterprise enables Weyco support resources to manage their printers globally from a central location.